Part 5 - More Work to the Top and Back

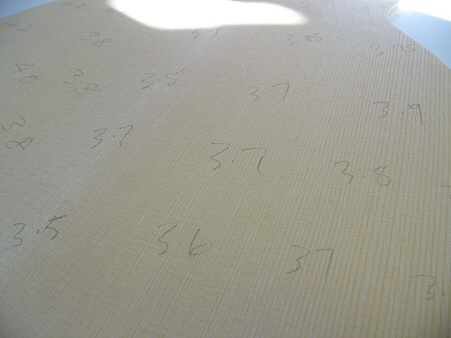

Now for some more thicknessing. Using dial callipers a thickness profile is penciled onto the top and then it is planed accordingly. The process is repeated until the desired uniform thickness is achieved. A thicknesser would be much easier but we’re using traditional methods here. Working on the inside surface, it will be reduced to just under 3mm. I’m working to tolerances of tenths of a millimetre. (Blimey....)

Making An Acoustic Guitar - Page 6

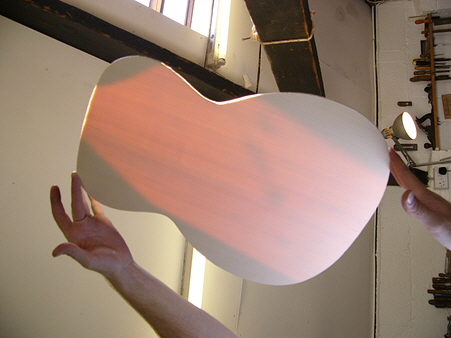

Getting close to the finished thickness now. You can see the vertical grain on the edge, the sign of a good quarter-sawn piece of timber. Notice the top is tightly grained in the middle and spreading out slightly at the edges - just what we want.