Making An Acoustic Guitar - Page 19

Starting at the waist - the tightest curve - it’s a case of gentle pressure and very gradual progress along the length of the side, checking every few millimetres against my plywood template. Two steps forward, one step back. The sides very slowly begin to take shape and patience, a philosophical calm (and perhaps some gentle whale music) are definitely the order of the day - or day and a half to be precise...

Part 14 - Bending The Sides

Now comes probably the scariest, and definitely the most difficult part of the whole build. Having thicknessed the two side blanks and and roughly cut them to size, they need to be persuaded that they don’t really want to be flat and boring any more, but would much rather adopt the sexy curves of a guitar.

This is done by bending them with a little water against a very hot tube called a bending iron. The art is to apply enough heat to soften the resins and tissue enough for the wood to become pliable, but without scorching it (or...*shudder*... snapping it in two). It’s also advisable to avoid putting your fingers on the iron.... (‘cos it’s BLOODY hot!)

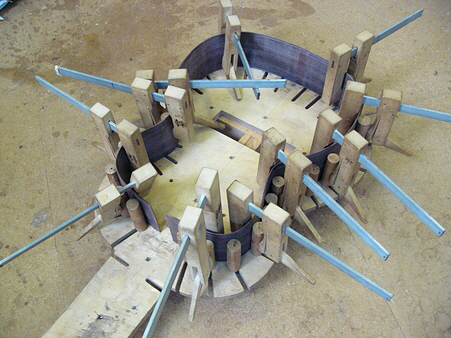

Finally, I can clamp the sides in the gluing mould while they get used to their new shape. I prepared the mould earlier using my trusty body template.