With the tentellones all in position I can now cut the sides down to the right depth. A Martin Triple-O measures 105mm at the end block and 85mm at the heel, so, allowing for the top and back, that’s where I need to be with my sides.

Using my trusty template, I mark out the depth at the neck, 1/8, 1/4, 1/2, 3/4, 7/8 and end block positions. Using a flexible straight edge I then join these positions together to form the datum line for the back. Then I carefully plane the sides down to the datum line.

Making An Acoustic Guitar - Page 21

Part 15 - Assembly - continued

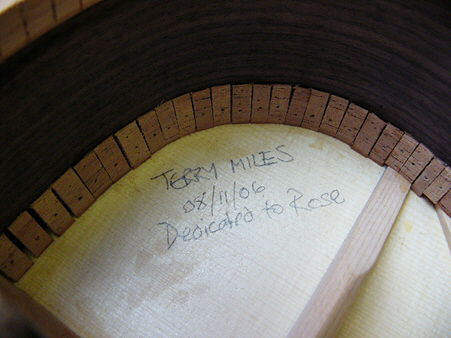

Now comes the laborious job of gluing individual tentellone wedges to make the top-to-sides join. Another reason why most people use a dovetail joint (where continuous kerfed lining can be used), but it’s the way it was done in the old days and this method ensures that there is a very strong, continuous join where the top meets the sides. Each wedge is speared with a bradawl, glue is applied, and the wedge is placed into position. It took me five hours to do this job but I have the satisfaction of knowing that every wedge (all 186 of them....) is firmly seated in the right position.